Coating Facility

What is coating facility?

With the advancement of science and technology, synthetic coatings using synthetic high molecular substances are widely applied throughout modern industries. The functions of coating include weatherability, corrosion resistance, prevention of adhesion of foreign bodies, heat insulation and smooth appearance. They are closely related with our life. The attention on eco-friendly coatings such as water soluble coatings and high solid coatings is increasing. In response to this, we are focusing on coating facility sector demanded by customers based on technology and experience accumulated over 20 years.

Coating Procedure

This equipment removes dirt and cleans the surface of vehicle body using chemical treatment. This procedure prepares for the optimum coating spray condition. Based on our experience in facilities for completed vehicles and automobile parts, we are taking responsibility in supplying preprocessing equipment suitable for the properties of object by taking consideration of customer demand from designing to production, installation, test operation and maintenance.

This coating method is used to coat a workpiece by setting the workpiece and tank as electrodes on each side and flowing current into water soluble paint inside the tank. It has less coating loss compared to immersion coating or spray coating. Also, automated process and coat reduction can reduce raw cost. As the undercoat (corrosion-proof coating) in completed vehicle industry and parts companies, the accessories include U.F. (Ultra Filtation) equipment and anode sell device.

This equipment is used to cure the coating on the surface of vehicle by using hot air. This process is important as it influences the coating quality. Air inside drying furnace is circulated by force to increase the air temperature inside the furnace by using heaters (gas, steam or electric heaters, etc.) during circulation. Its biggest advantages include possibility of uniform drying coating, wide temperature control range, and variety of heat sources. As it can be influenced by external factors, designing, production and installation are especially important.

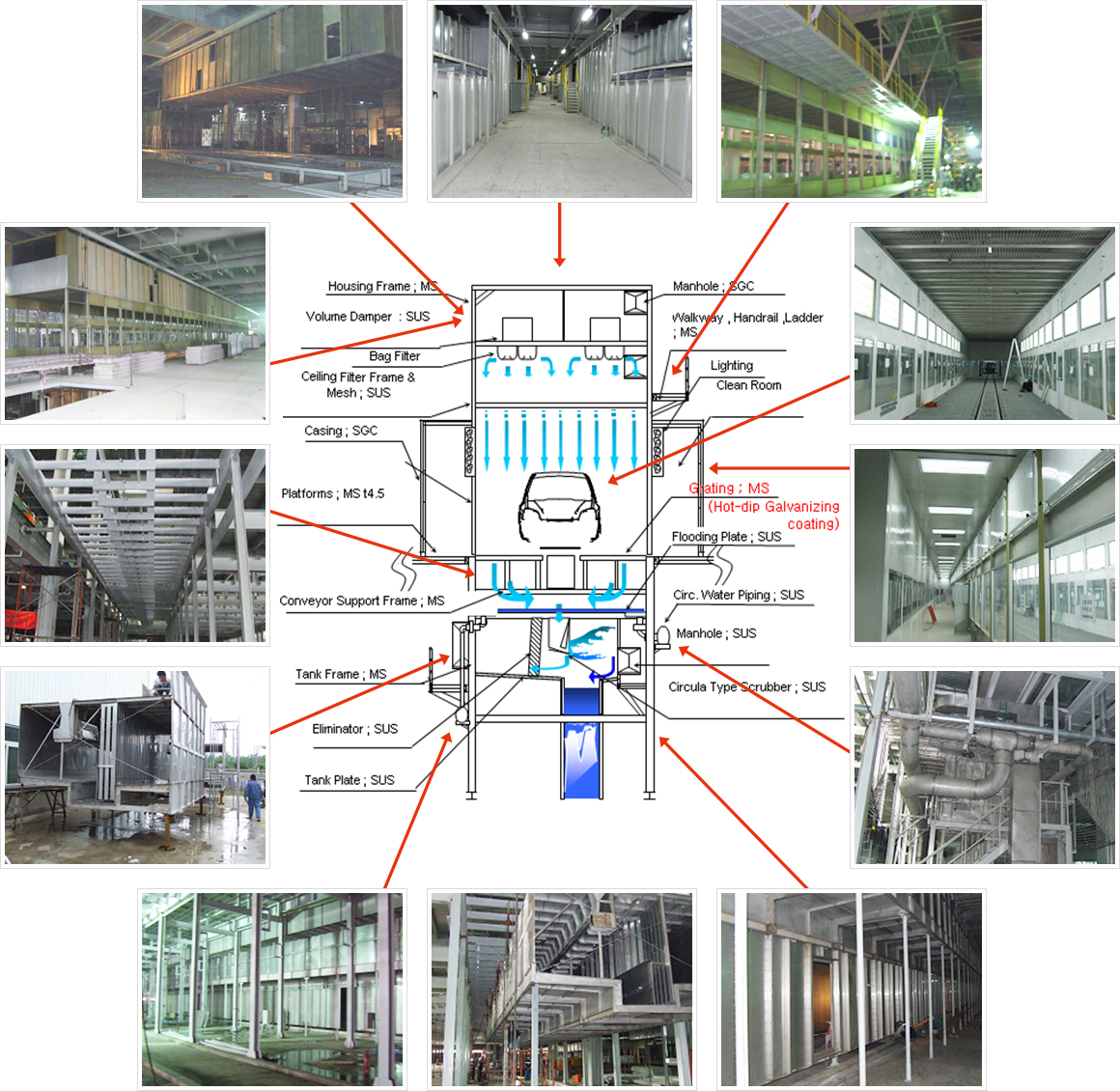

This facility is used for paint spraying onto the surface of vehicles. In this important process, various factors such as temperature, humidity and dust prevention influence the coating efficiency. Depending on coating type, special auxiliary facilities are needed.

Auxiliary Facilities: A/C Tower, C.W.S., Exhaust System, Air Handling Unit, etc.

Booth Types: Spray Booth (Primer, Topcoat, Powder), Repair Booth Polishing, etc.

This equipment is used to supply air inside spray booth and working area to optimum condition necessary for coating procedure. Coating quality is influenced by surrounding environment, hence to assure supply of suitable air quality, a precide A.H.U. is essential. Its precise temperature and humidity control and dust removal function influence the coating quality.

Components of A.H.U.: Roll Filter, Heat Source (Gas Burner or Steam Coil), Washing Zone, Cooling Coil, Supply Fan, etc.

Coating Facility/Installation Case

- Initial design step: Reflect problems in existing plant facility

- After basic designing, review facility operability/workability/preservation

- Review details production design drawing: Structural durability (to prevent production defect)

Specification Consulting

Specification Consulting

(Technical Review)

Set Plan

Set Plan

(Schedule, Quality)

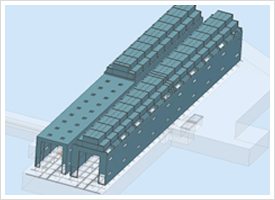

Draft Design

Draft Design

(Working Design)

Drawing Approval

Drawing Approval

(3D Design)

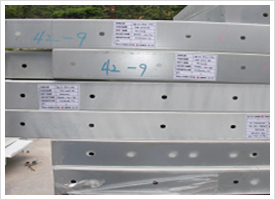

- Lot test prior to warehousing major functional and processed goods: Accuracy Inspection, Durability Test

- Confirming inspection compared to production structure design drawing: Visual Inspection, Welding Inspection, O.L.T.

- Warehouse management after major equipment test: Purchased items such as fans and burners

Warehousing Raw Materials

Warehousing Raw Materials

(Order Functional Goods)

Canning & Welding

Canning & Welding

(QC Reinforcement)

Assembly Test

Assembly Test

(O.L.T.)

Coating Procedure

Coating Procedure

(Base Coat, Top Coat)

- Label serial number and package parts and products for each equipment: Jig and pallet packaging

- Check for damage in parts and products during loading/unloading: Appearance and deformation test

- Post-management after on-site warehousing: Protect products from pollutants such as rust and dust (Cover with vinyl or tarpaulin)

Packaging & shipping

Packaging & shipping

(By unit equipment)

Transportation

Transportation

(Fixed quantity loading)

On-site warehousing

On-site warehousing

(stand-by for installation)

Parts classification

Parts classification

(tag confirmation)

- Warehoused goods inspection prior to installation / accuracy test for installation quality: Assembly quality, welding quality, coating quality, etc.

- SPEC compliance: Performance, function, assembly dimensions

- Occupational accident preventive measures: Safety manager stationed for high place works and heavy load works

- Instalt measures to problems during installation or production

Check coordinate

Check coordinate

(mark)

Field installation 1

Field installation 1

(A/C tower)

Field installation 2

Field installation 2

(booth frame)

Field installation 3

Field installation 3

(air supply duct)

- Supervisor permanently stationed: Reinforced management in installation and test operation

- Check functions and performance of facility: Instant improvements for unsatisfactory areas

- Production and repair education: Sufficient training prior to mass production, support mass production

- Provision of relevant books and guidelines: Provide operation and repair manuals

Check I/O

Check I/O

(automatic control)

Performance test

Performance test

(supply/exhaust faclity)

Load test

Load test

(wind amount, wind speed)

Test production

Test production

(actual vehicle)

Coating facility installation flow

Coating booth

- 1) Putty worksite

- 2) Polishing worksite

- 3) Putty worksite

- 4) Masking worksite

- 5) Vehicle body under coat booth

- 6) Vehicle body top coat booth

- 7) Coat drying booth

- 8) Other(lifts and elevators)

Coating Facility Image

Produced and installed clean room in Beijing Hyundai/2 Coating Plant (top coat booth)

Produced and installed clean room in Beijing Hyundai/2 Coating Plant (top coat booth)

Produced and installed clean room in eijing Hyundai/2 Coating Plant (under coat booth)

Produced and installed clean room in eijing Hyundai/2 Coating Plant (under coat booth)

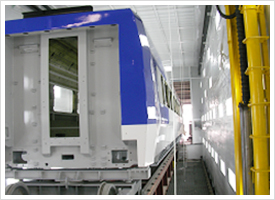

Produced and installed in Hyundai Rotem/Railway vehicle coating plant (U/F top coat)

Produced and installed in Hyundai Rotem/Railway vehicle coating plant (U/F top coat)

Produced and installed coating booth in Beijing Hyundai/2 Plant (top coat booth)

Produced and installed coating booth in Beijing Hyundai/2 Plant (top coat booth)

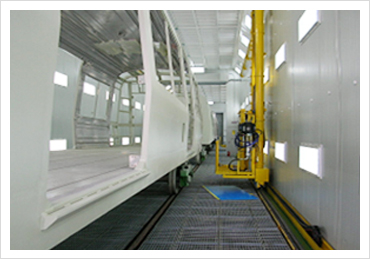

Produced and installed top coat booth in Hyundai Rotem/Railway vehicle coating plant (dual function with oven)

Produced and installed top coat booth in Hyundai Rotem/Railway vehicle coating plant (dual function with oven)

Produced and installed under coat booth in Hyundai Rotem/Railway vehicle coating plant

Produced and installed under coat booth in Hyundai Rotem/Railway vehicle coating plant

Installation of coating booth in Beijing Hyundai 2 Plant (process)